Create printed rolls of flexible packaging on demand, laminated and ready for pouch making in HFFS or VFFS machines. The FP-230 Flexible Packaging Press is perfect for small to medium runs or varying print designs. Print small-format flexible packaging on demand with inkjet-printable Artysio Packaging Films from Sihl, a global leader in the manufacturing of narrow and large format digital printing media and paper supplies.

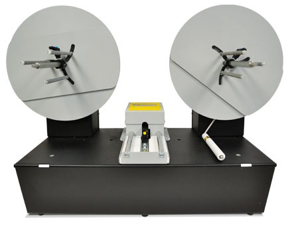

The FP-230 has revolutionized packaging roll production. Impressively compact and easy to operate, the FP-230 lets you print and laminate your own high-quality, full-color flexible packaging with ease. Ideal for small to medium runs and high levels of varying data or design, the FP-230 is a groundbreaking solution that opens the door to endless opportunities. All on-site, all on-demand.

- Production speed up 18m/minute

- Exceptional 1600dpi resolution

- EU & FDA food complaint

- Easy variable data

- No minimum order quantities

Stunning Digital Inkjet Printing

The FP-230 uses the L901 Plus printer to produce vibrant, full-color prints on rolls up to 230mm wide with a maximum speed of 18 m/min. Variable data and color matching are handled with ease by the optional Northstar RIP. The water-based inks have been approved for food packaging when combined with the in-line cold lamination, with your finished roll trimmed to the perfect width using the two rotary knives.

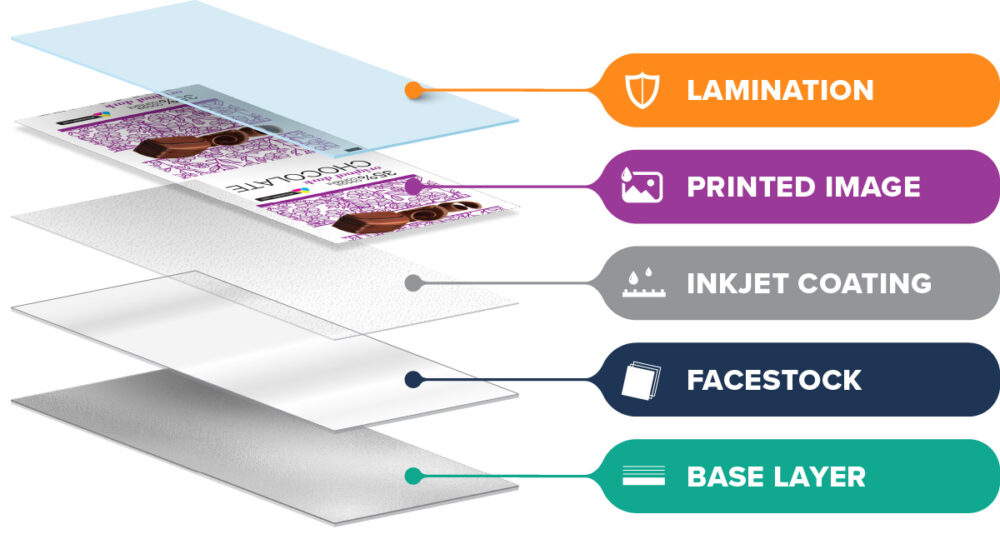

High-Performance Sihl ARTYSIO Films

Sihl’s ARTYSIO range of high-performance packaging films is optimized for the FP-230. These films provide strong functional barriers and sealing properties, making them perfect for a wide range of demanding product applications including cosmetics, supplements, pharmaceuticals, liquids, and foods.

Reduce Waste, Time & Stockholding

The FP-230 enables “just in time” roll production, which removes the need to hold stock of pre-printed rolls. When compared to traditional production methods such as Flexo and Roto, it significantly reduces plastic waste by using only 3m of film for job setup. Increased sustainability is also possible with Sihl’s ARTYSIO PP films, which are independently certified as “made for recycling”.

In-house production of flexible packaging has never before been an option. But now, with the Afinia Label FP-230, it’s fast, affordable, and easy.

From print to pack in minutes.

Create printed rolls of flexible packaging on demand, laminated and ready for pouch making in HFFS or VFFS machines. The FP-230 Flexible Packaging Press is perfect for small to medium runs or varying print designs. Print small-format flexible packaging on demand with inkjet-printable Artysio Packaging Films from Sihl, a global leader in the manufacturing of narrow and large format digital printing media and paper supplies.

The FP-230 has revolutionized packaging roll production. Impressively compact and easy to operate, the FP-230 lets you print and laminate your own high-quality, full-color flexible packaging with ease. Ideal for small to medium runs and high levels of varying data or design, the FP-230 is a groundbreaking solution that opens the door to endless opportunities. All on-site, all on-demand.

- Production speed up to 18m/minute

- Exceptional 1600dpi resolution

- EU & FDA food compliant

- Easy variable data

- No minimum order quantities

FP-230 Details

Stunning Digital Inkjet Printing

The FP-230 uses the L901 Plus printer to produce vibrant, full-color prints on rolls up to 230mm wide with a maximum speed of 18 m/min. Variable data and color matching are handled with ease by the optional Northstar RIP. The water-based inks have been approved for food packaging when combined with the in-line cold lamination, with your finished roll trimmed to the perfect width using the two rotary knives.

High-Performance Sihl ARTYSIO Films

Sihl’s ARTYSIO range of high-performance packaging films are optimized for the FP-230. These films provide strong functional barriers and sealing properties, making them perfect for a wide range of demanding product applications including cosmetics, supplements, pharmaceuticals, liquids and foods.

Reduce Waste, Time & Stockholding

The FP-230 enables “just in time” roll production, which removes the need to hold stock of pre-printed rolls. When compared to traditional production methods such as Flexo and Roto, it significantly reduces plastic waste by using only 3m of film for job setup. Increased sustainability is also possible with Sihl’s ARTYSIO PP films, which are independently certified as “made for recycling”.

In-house production of flexible packaging has never before been an option. But now, with the Afinia Label FP-230, it’s fast, affordable and easy.